Our goal from day one was to create a world where eyewear is not only responsibly produced, but also truly tailored to the individual. That’s why our guiding principle has always been: “Faces come in billions of shapes and sizes. Eyewear should do the same.”

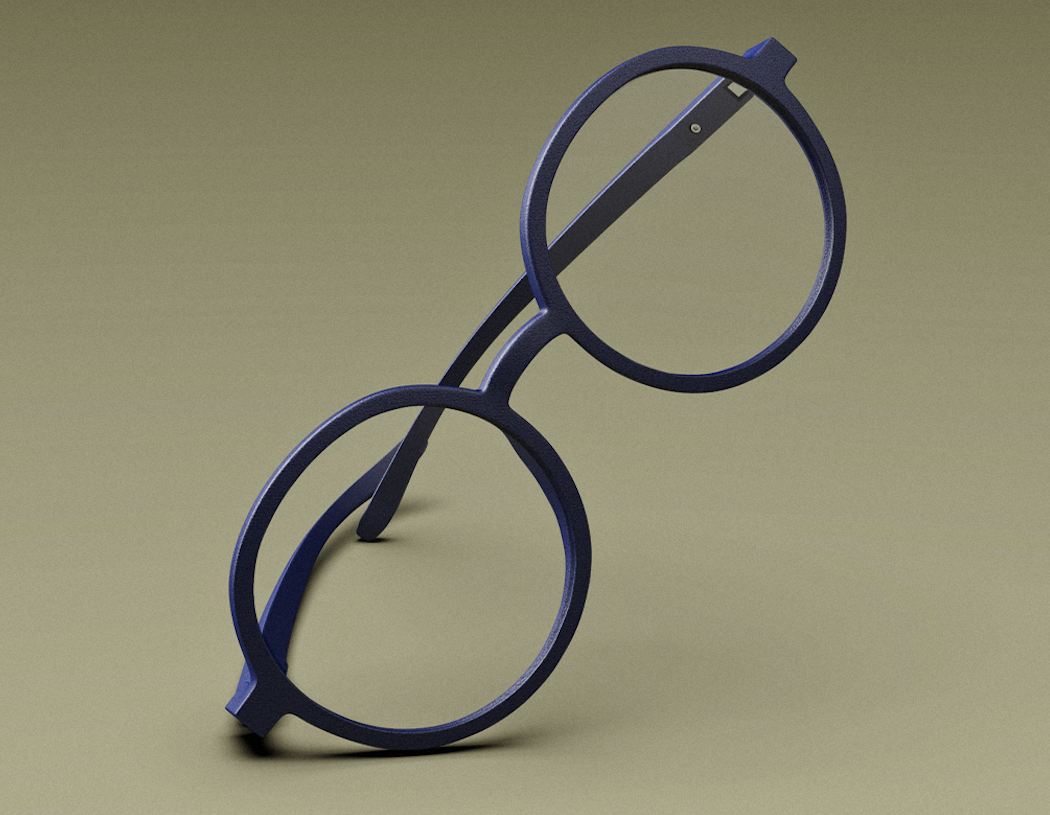

Looking back now in 2025, this vision is more relevant than ever. Technological advancements, especially in 3D scanning and additive manufacturing, have allowed us to stay true to this core idea — not just in theory, but in practice. And that’s something we’re incredibly proud of. Above: YOUMAWO model Dione, clean lines for a modern, elegant finish

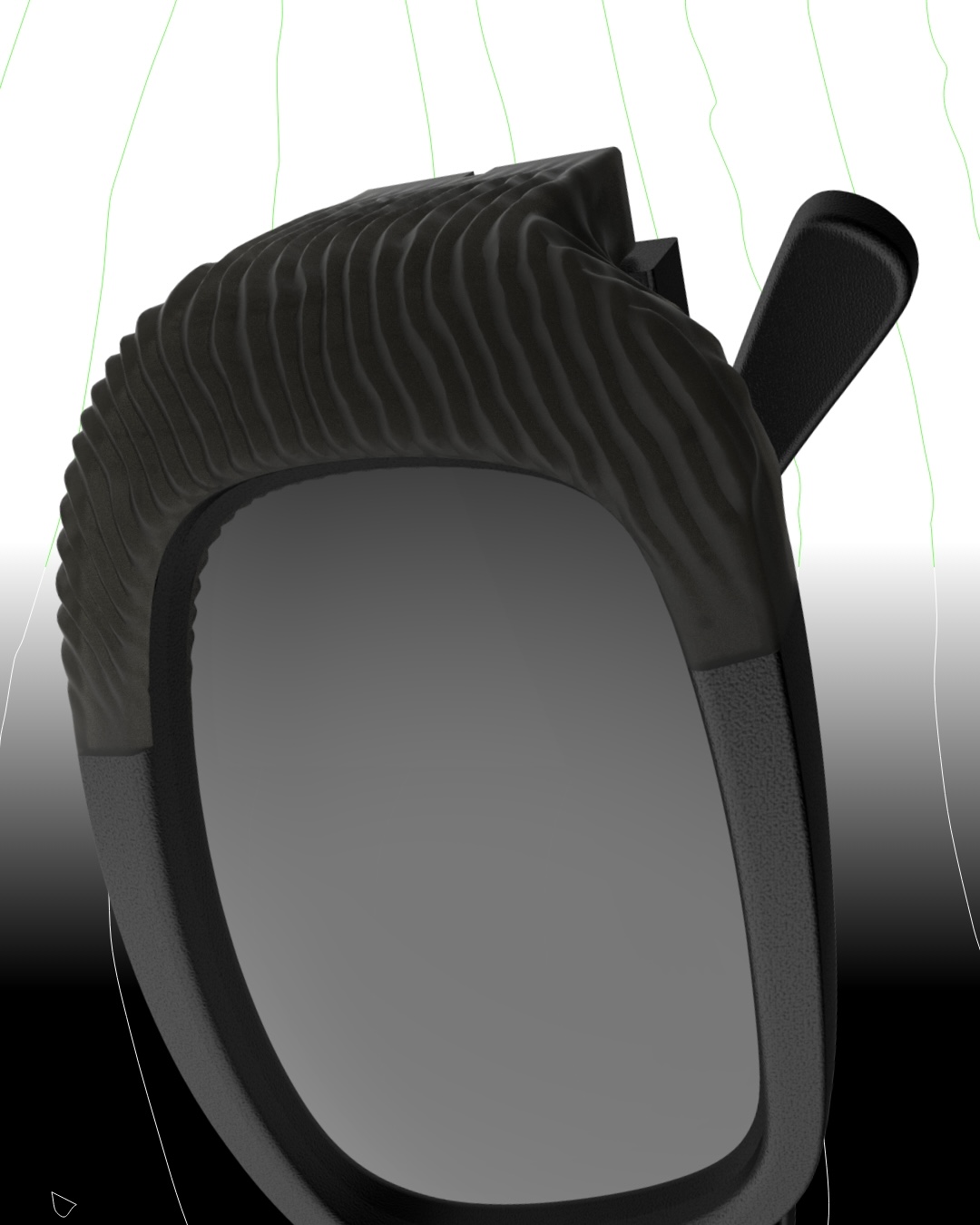

Over the years, what design steps / innovations / or products have you been most proud of and why. There are several aspects of our work that we’re especially proud of. From a design perspective, our Capsule Collections and the creations within the YOUNIVERSE have allowed us to push boundaries — both aesthetically and technically. These projects serve as a kind of experimental space where we test new materials, explore unconventional shapes, and reimagine what eyewear can be.

On the customization side, we’ve consistently challenged ourselves to improve our system. It’s not just about making custom eyewear accessible — it’s about refining every step of the user journey, from facial scanning to fit analysis to production. This constant questioning of the status quo is a defining part of our culture at YOUMAWO, and it’s something we see as essential to innovation.

Are we in a good place with the 3D printed eyewear offer already in 2025, or do you think there is a lot more potential and design innovation to come, particularly seeing as smart glasses are also back in the headlines this year? We’ve definitely come a long way, and the level of sophistication in 3D-printed eyewear today is remarkable — especially in terms of material quality, precision, and individualization. But we believe we’re still just scratching the surface.

Additive manufacturing offers unmatched flexibility when it comes to design freedom and personalization, and we see tremendous untapped potential — especially when it comes to integrating technology. Smart glasses are back in the spotlight, and the convergence of custom fit and smart functionality is a space where we see unique opportunities. Our manufacturing approach enables us to create solutions that are not just smart, but also comfortable, stylish, and truly tailored to the wearer — something mass-produced smart glasses often lack, that’s why we see plenty of room for smart glasses to give them the comfort they need.

Do you feel that 3D printed eyewear has gained more recognition in the last couple of years as a prestige design product? Absolutely. There’s a growing appreciation for the possibilities that additive manufacturing brings to the world of high-end eyewear. What was once seen as a niche or experimental approach is now being embraced by more and more designers — and even luxury brands — as a serious, forward-thinking production method.

We’re seeing the perception shift: 3D-printed frames are no longer just about technical innovation — they’re being recognized for their design value, for their sustainable production process, and for their ability to offer a truly personal product.

Has the introduction of AI opened up doors for your work at YOUMAWO and if so how? Yes, AI has become an increasingly valuable tool in many areas of our work. We’re especially intrigued by its potential in the design process. Rather than replacing creative thinking, we see AI as a kind of sparring partner — one that allows us to challenge our ideas, discover unexpected forms, and introduce new dynamics into our design language.

Beyond design, we also see potential in areas like fit optimization, customer interaction, and even predictive personalization — helping us to better understand what people need before they even realize it themselves. We’re still in the early stages, but the possibilities are truly exciting.

In 2025, can you reveal what has been your favourite design project so far and why. In 2025, we’ve really focused on going back to our roots — questioning who we are as YOUMAWO and what defines our design language. We reflected deeply on our core, and that was truly great — it gave us a clearer picture of who we are and what makes us unique.

What are you working on this month and are you preparing something special for Autumn/Winter 2025/26? We’re currently working on several projects. And yes, of course we have something planned for Autumn/Winter — but we’re not revealing it just yet. We want to keep it exciting!